Ensuring Industrial Durability

How Paint Innovators Maximizes Coating Life Through Industry Standards & Advanced Systems

At Paint Innovators, we understand that longevity in industrial and commercial coatings starts with strategic planning, expert application, and ongoing compliance. Our mission is to protect infrastructure while helping facility managers avoid premature degradation and costly repairs through long-lasting solutions.

From specification to execution, we align every project with industry standards like SSPC, ISO, ASTM, and NACE to deliver reliable, performance-driven coating systems designed to stand the test of time.

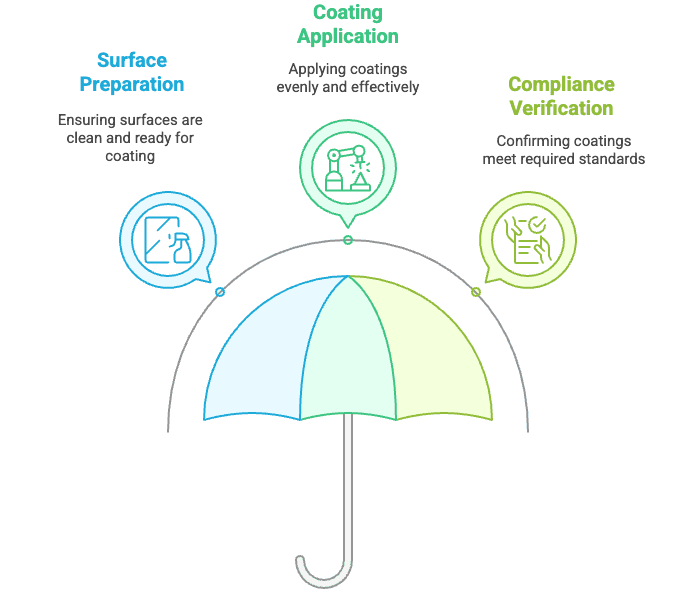

Components of Advanced Coating Systems

Overview of Industrial Coatings We Use

Facilities face exposure to aggressive elements—chemical fumes, humidity, and temperature shifts. That’s why Paint Innovators leverages epoxy, maintenance coatings, and architectural coatings for comprehensive protection and extended lifespan of substrates.

Our team selects coating systems based on exposure type and performance requirements—enhancing abrasion resistance, corrosion control, and surface aesthetics across sectors including healthcare, education, and manufacturing.

Surface Preparation: The First Step to Coating Longevity

SSPC-SP 6/NACE No. 3 – Commercial Blast Cleaning

Proper adhesion starts with the right prep. Our abrasive blasting services follow SSPC-SP 6 guidelines to eliminate surface contaminants, rust, and old coatings—laying the foundation for coatings to perform as intended.

SSPC-PA 2 – Dry Coating Thickness Verification

We ensure the longevity of every coating system through SSPC-PA 2-compliant thickness checks. Our team uses calibrated gauges to verify uniform application and prevent premature wear due to under- or over-application.

Surface Preparation & Measurement In Action

Compliance Standards That Extend Coating Life

ISO 12944-2 – Corrosion Protection

We tailor our systems to match ISO 12944-2 environmental classifications—especially in aggressive C5-M zones—ensuring steel structures resist salt, humidity, and pollutants for decades.

ASTM D3273 – Mold Resistance

For interior surfaces, we use coatings tested under ASTM D3273 to resist mold growth in environments like commercial kitchens and HVAC zones. This helps preserve both hygiene and coating integrity.

NACE SP0188 – Holiday Testing

Pinholes and voids are enemies of coating performance. That’s why our team performs high- and low-voltage holiday testing on critical structures—eliminating hidden weak points before they become problems.

Coating Testing Methods and Applications

Sustaining Performance Through Integration & Maintenance

Corrosion Resistance

By combining standard compliance with real-world experience, Paint Innovators develops coating plans that withstand harsh exposures and prevent degradation—protecting clients’ investments long-term.

Preventative Maintenance

Our coatings are only the beginning. We advise clients on proactive inspection and cleaning schedules aligned with ASTM D3273 recommendations to catch early signs of failure and maximize return on coating investment.

Thickness & QA Programs

Every project is supported by our SSPC-PA 2-based QA protocols—ensuring coating thickness, consistency, and performance meet long-term expectations.

Paint Innovators' Approach to Coating Longevity

Our team integrates the full spectrum of coating best practices—surface prep, material selection, and verification—so clients get more than a coating; they get a long-term protection strategy.

With regular inspection and strict adherence to SSPC, ISO, ASTM, and NACE standards, Paint Innovators helps facility managers extend coating life, cut future costs, and ensure durable, lasting results.

Industrial Coating Durability Pyramid